Monitoring

Cave maturity

Monitoring the hazard mechanisms

Rainfall

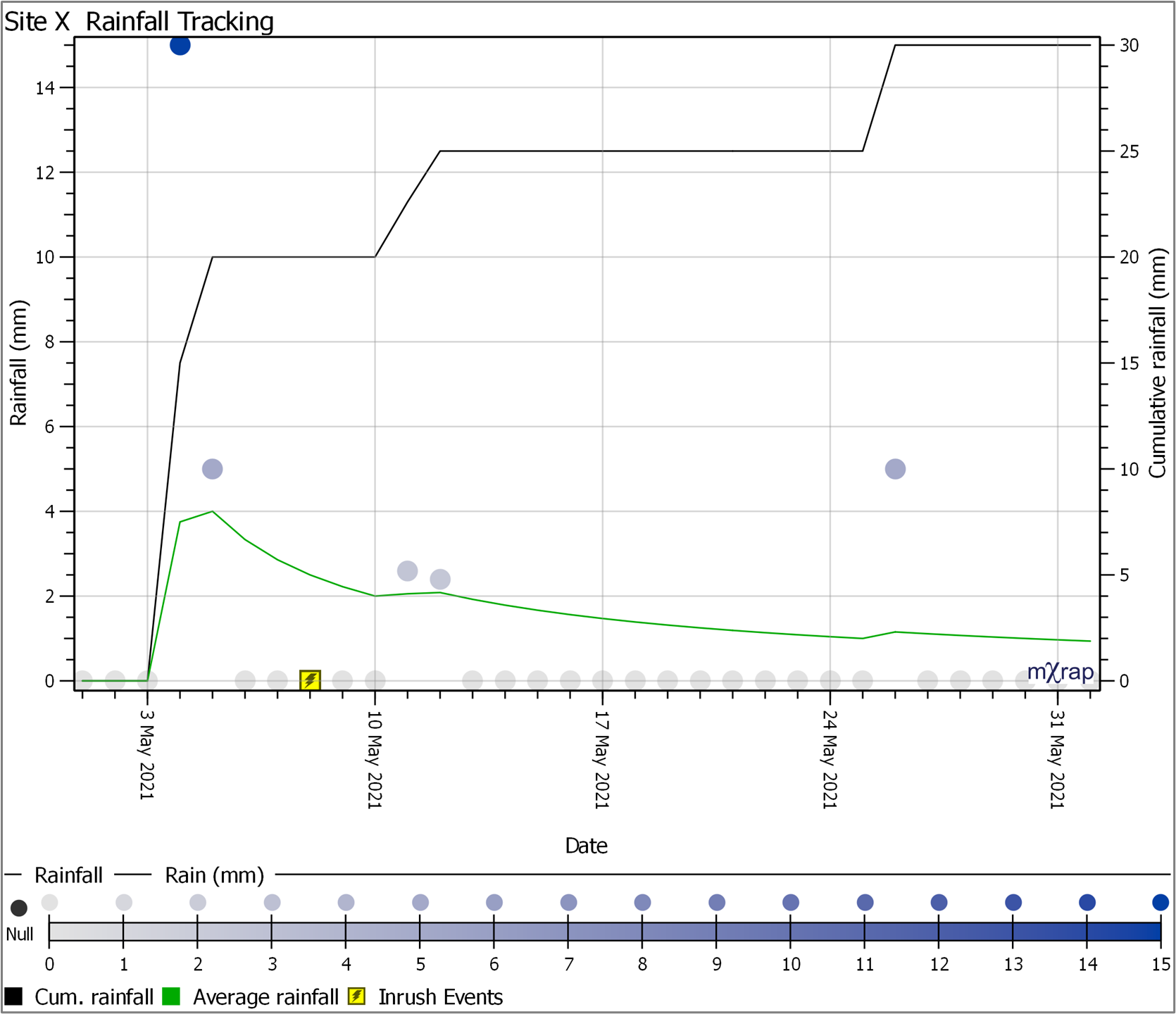

With water being a key mechanism in many inrush occurrences, particularly in tropical and sub-tropical locations, there is often a link between the amount of rainfall and the occurrence of an inrush event (Figure 8). Delays between the rainfall event occurring and the water percolating to the extraction level is a complex factor influenced by cave maturity, bogging compliance, fragmentation, column height etc. Being able to visualise the two data sets can support visual trend analyses.

Figure 8 Rainfall from weather station with inrush event occurrences indicated.

Figure 8 Rainfall from weather station with inrush event occurrences indicated.

Fragmentation

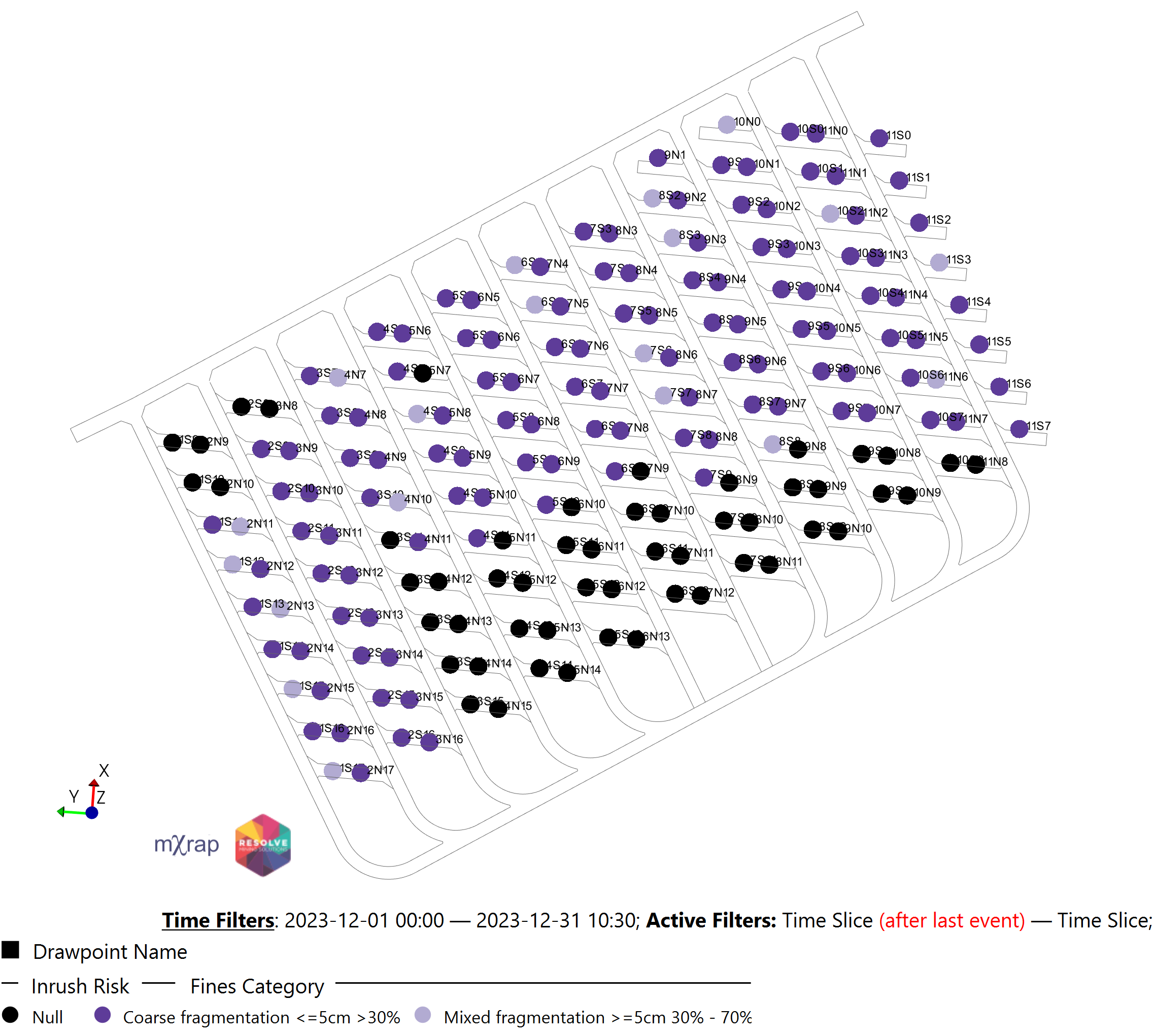

Within the mXrap caving app suite, a fragmentation app already exists which enables the user to interrogate data and changes over time. The fragmentation component of the inrush management app takes this data and considers the % of fines as a key risk indicator of exposure to inrush hazards. This parameter feeds directly into the calculation of inherent risk, discussed in later sections. It can also be visualised in plan view against each drawpoint as shown in Figure 9.

Figure 9 Fragmentation classification based on inrush risk.

Figure 9 Fragmentation classification based on inrush risk.

Monitoring the adherence to controls & their effectiveness

There are several controls that are available to operations for managing the exposure of personnel to inrush risk. The following section demonstrates bunding status and extraction method within the Inrush Management App. However, additional features can be incorporated with site specific categories and requirements added as needed. TARP triggers and reporting are also outlined as a feature to support effective communication with all site personnel.

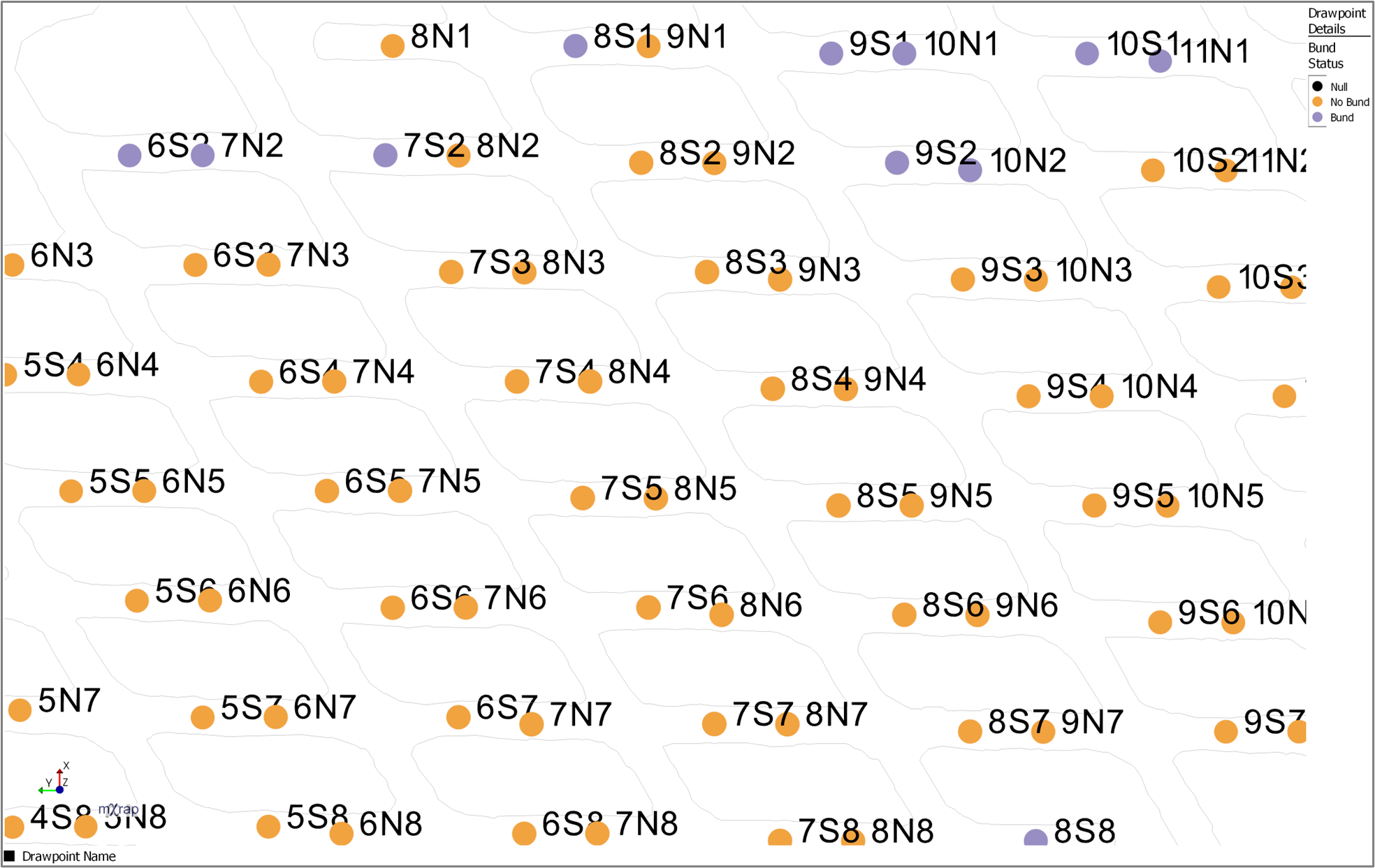

Bunding status

Bunding is used as a typical control across most operations for managing uncontrolled movement of material out of a drawpoint and understanding where on the level bunds are in place and where they are not, compared to site standards, forms a key control and verification activity which has shared responsibilities across team leaders, superintendents, and site management. Existing systems of reporting through to mine control or equivalent can be integrated into importing this data directly into mXrap for seamless visualisation. In the example shown in Figure 10, an accessible colour palette is used with a simple "Bund" or "No Bund" category assigned.

Figure 10 Visual tracking of drawpoint bund status

Figure 10 Visual tracking of drawpoint bund status

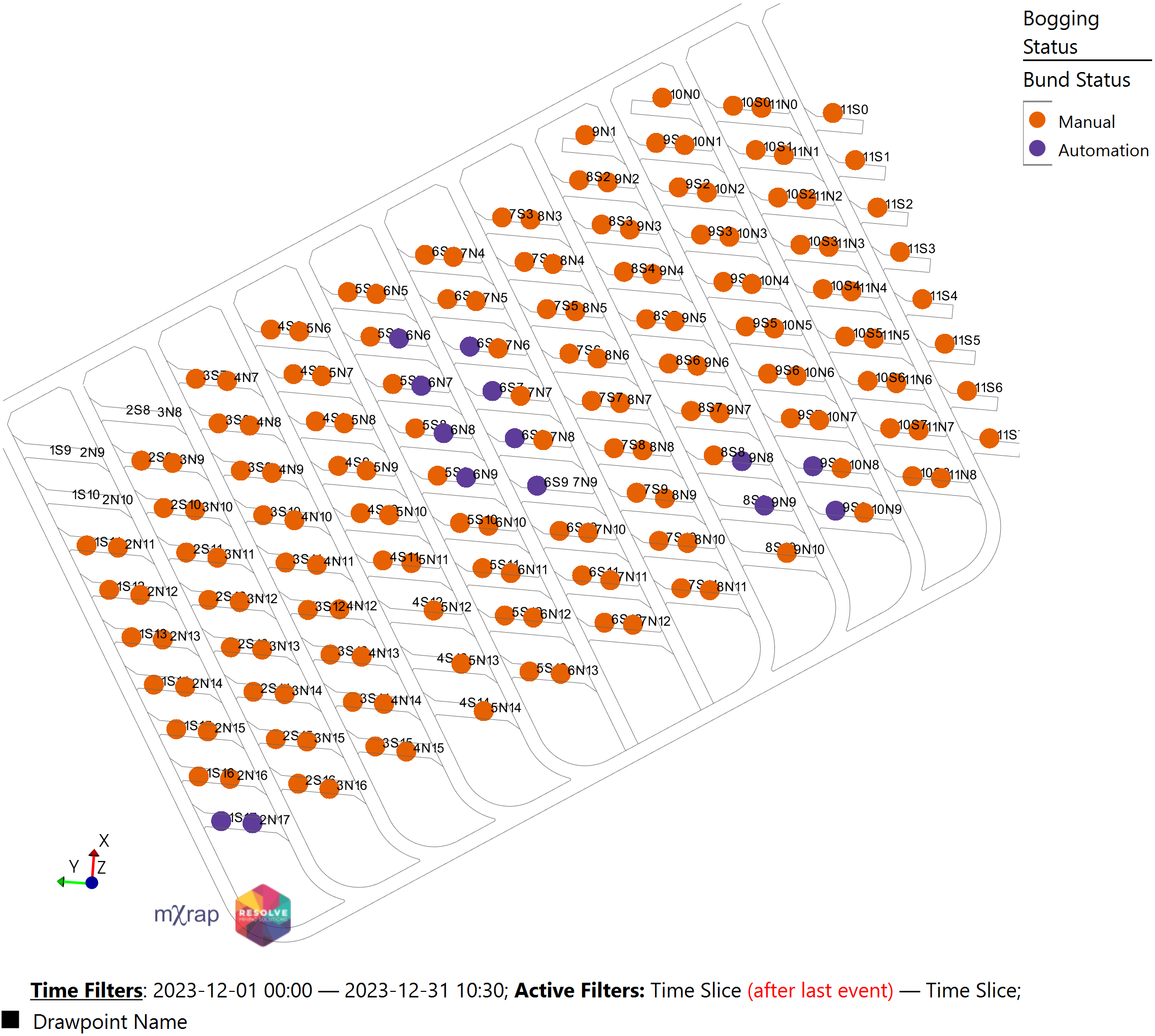

Operational controls

With advances in technology, remote and autonomous operation of LHDs is becoming standard practice at mines around the world. It is also a control used for management of exposure to inrush risk due to the removal of personnel from the cab, and therefore from the line of fire, should an inrush event be triggered during mining. Depending on the layout of the extraction level, the increased inrush hazard can impact multiple drawpoints, and in the case of dead-end headings, requires the rest of the drive to be bogged on remote/autonomously to control the hazard exposure past the impacted drawpoint for both inrush and entrapment.

Figure 11 Bogging restrictions across the extraction level

Figure 11 Bogging restrictions across the extraction level