Using mXrap to support risk management

WHS obligations - risk management and critical control verification

WHS laws and mining legislation in most jurisdictions prescribe that mine operators have a duty of care to their workers and visitors to manage exposure to risk. Typically, this involves a series of risk assessments laying out hazards and identifying controls, which are then implemented to control the relevant hazard and reduce the risk to an acceptable level. An essential, but at times difficult to implement, part of the risk management process, is critical control verification. This creates a feedback loop to check how well the controls identified in the risk assessment are working to reduce the identified hazards. Controls that are working are continued to be maintained, but inadequate controls require a review of the risk assessment and triggering of subsequent controls. This whole process is documented and forms part of the site's auditable risk management framework.

Controls for some hazards can be more easily verified than others. Take the example of working on scaffolding where the hazard is that the worker is exposed to a risk of falling from height. There are engineered controls such as spring-loaded safety gates, railings, and anchor points, along with fall arrest and fall restraint harnesses (PPE), qualifications for scaffold riggers and limits around working in strong winds, along with training and assessments for the people working on the scaffold. These elements can all be verified by reviewing records of inspection, certificates for training, on the job inspections etc. This makes the control verification a relatively simple process, if record keeping is maintained in a logical and organised manner.

However, managing many hazards isn't that simple. In some instances, even advanced visualisation tools struggle to provide a complete picture, particularly of multiple changing data sets and source are utilised. Using mXrap as a platform, Resolve has been developing an app, designed to assist operations in visualising data that is typically used to guide inrush Trigger Actions Response Plans (TARP)s. By integrating multiple data sources into one location, utilisation of the data becomes more streamlined and effective and the control verification component of the risk management framework becomes easier to validate.

Inrush Management

Inrush is defined as a Principal Mining Hazard in the Mining Acts and Regulations across Australia, meaning it has been identified as a hazard with the potential to cause multiple fatalities in a single event or series of recurring events.

The NSW Department of Primary Industries (now NSW Resource Regulator) released Mine Design Guideline (MDG) 10241 in 1998 later updated in 2007, with the aim of providing general guidelines to assist mine owners and managers in developing an Inrush Management Plan. Whilst it was originally developed for coal mining, it still contains relevant information for metalliferous mines and caving operations. Particularly block cave operations, are typically exposed to inrush hazards on a more frequent basis than other mining methods due to the nature of mining in a static environment.

MDG-1024 outlines "The Inrush Risk Assessment Process" and highlights three different ways of monitoring major hazards:

- Monitoring the status of the hazard

- Monitoring the mechanisms by which the unwanted event occurs, and/or

- Monitoring adherence to key controls

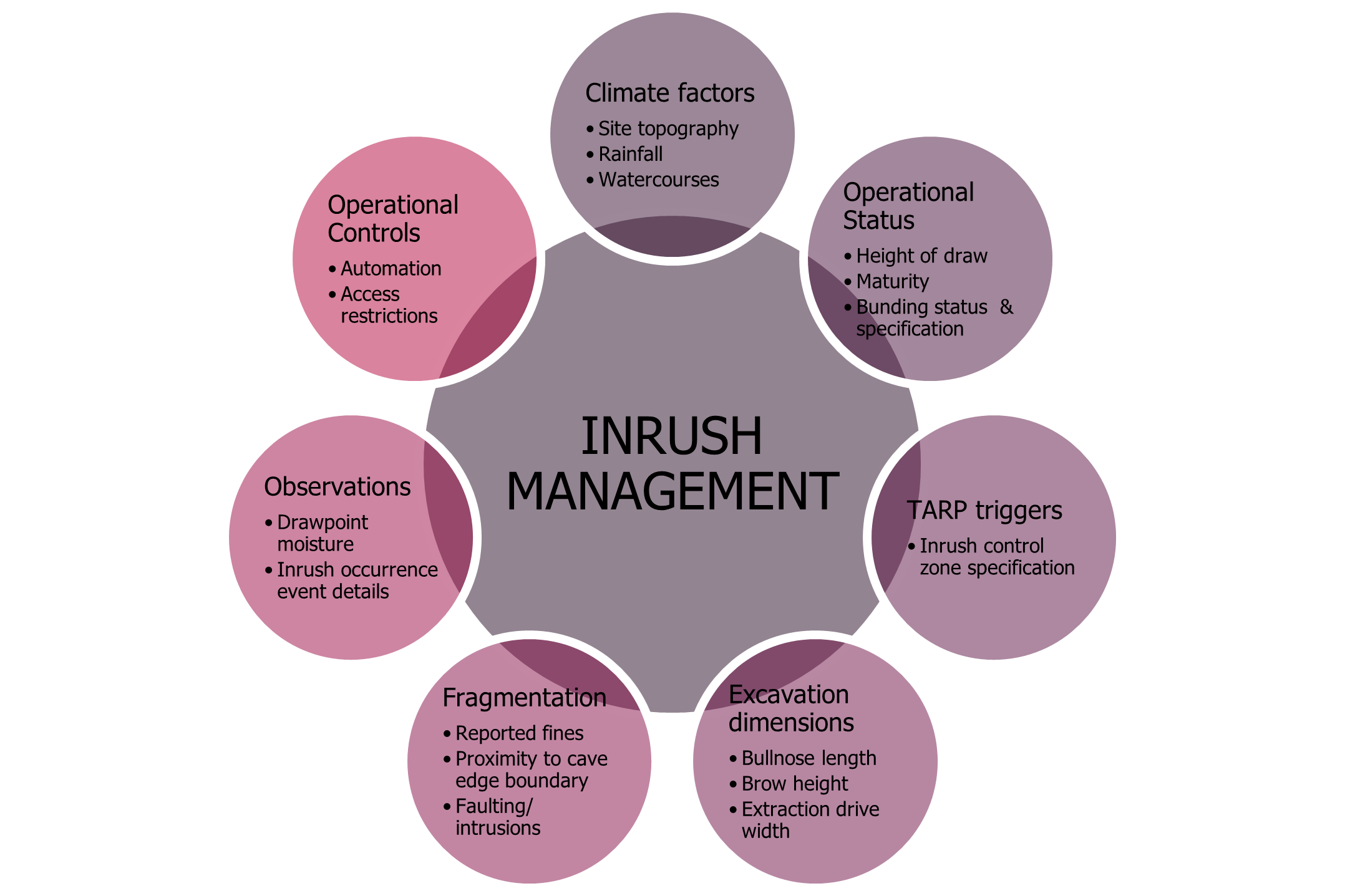

Based on experience with block cave monitoring, there are key elements that all caves monitor in some capacity across these three categories:

Status (how is a mine performing with regards the hazard)

- Drawpoint moisture

- Excavation dimensions

- Cave maturity

- Historical performance/occurrences of inrush events

Mechanisms (what is required for the inrush event to occur)

- Rainfall (and any other water sources into the cave column)

- Fragmentation

Adherence to controls (are the controls being used and how often?)

- Bunding status

- Excavation method (manual, remote, automation)

- TARP triggers and response

Figure 1 Elements associated with inrush management

Figure 1 Elements associated with inrush management

mXrap app development

Prior to developing a solution for supporting inrush management, the project goals and objectives were defined. The scope of this project was to focus on a generic app that provides the framework for site customisation, with the main features of inrush management from Figure 1 included.

Goal

Provide easy to use interface for visualisation of key inrush hazard monitoring elements, allowing for streamlined reporting against the site Inrush Principal Hazard Management Plan.

Objectives

- Utilise existing data within other mXrap apps where relevant.

- Provide easy-to-use interfaces for data import and management.

- Automate required calculations to ensure consistency across users.

- Display data in functional formats for inclusion in reporting and critical control verification tasks

- Ensure that the user interface and associated outputs is compatible with colour blindness, printing and scanning as far as reasonably practicable.

The development of the app focused on the three ways of monitoring inrush as described in MDG-1024 detailed above. The following sections demonstrate the tools that have been developed and highlights how they can be customised for specific site requirements.

The mine layout used to demonstrate the features within this app consists of a standard El Teniente layout using fabricated data and does not represent a real operation. It is also important to note that all the tools described below can be filtered using the typical time filters available within mXrap, with video export possible if required to support presentations and communications across the operation. In addition, everything seen can be customised to any individual operation, based on pre-existing classifications, hazard matrices and input parameters.

Importance of accessible colour schemes

Current statistics in Australia indicate that around 8% of males and 0.4% of females suffer colour blindness to some degree (Vision Eye Institute, 20232). These statistics also can vary significantly by country as population densities and pre-disposition to genetic factors vary. Depending on where the operation is located, and the personnel demographic, these statistics may change. While colour blindness doesn't relate to a lack of vision, it does result in people having difficulty in identifying specific colours, particularly greens, yellows, oranges, and reds. Considering that typical colours associated with risk management are green through to red (good to bad), and the high percentage of males in the mining industry (80% based on FY22 statistics, Mining News, 20223), reconsidering the colour schemes used to promote effective communication is needed.